Are you getting shocked every time you walk up to your machine? Ever had a controller fail because of static discharge? You need one of these!

Newly updated for the 510/520 machines!

Finally, based on the help of several users, I’ve updated the kit to better fit and work with the newer 510 and 520 series machines. I’ve added a new Run / Probe switch box for those having issues using the Z-axis touch-off plate. I’ve updated the instructions as well.

Because of the significant changes in what you get, and because increased shipping costs that have risen over 40%, there’s a price increase.

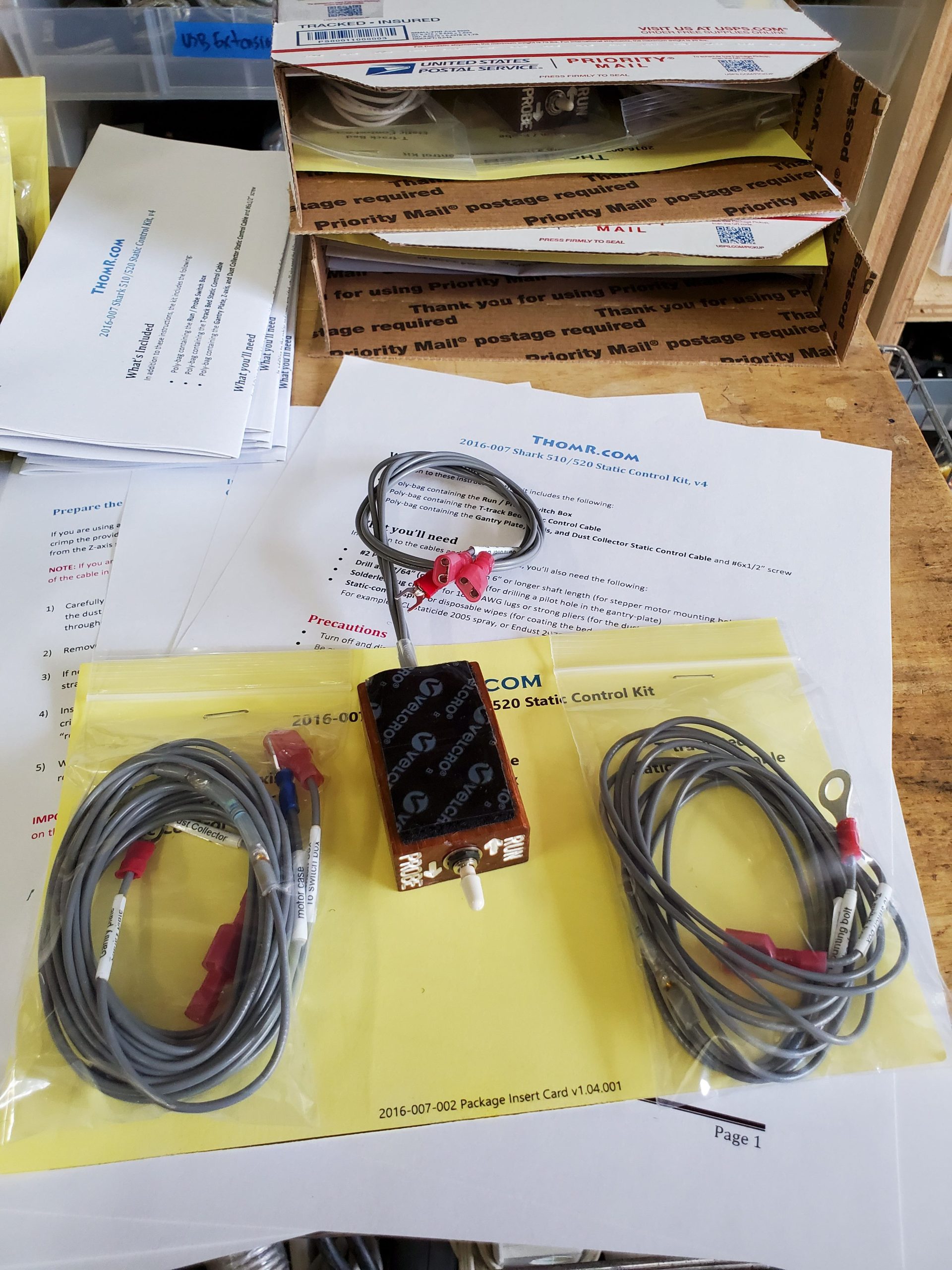

CNC Shark static control wiring kit

Get this before disaster strikes!

Drop me a note at thom@thomr.com, and for US$59+ $11 shipping I’ll ship one out to you. It includes two static control cables that properly tie together the bed, stepper motors, and gantry plate, and a Run / Probe Switch box for the newer machines, which can display issues with the touch-off probe when the structures are electrically tied together. All the lugs and connectors are clearly labeled for easy installation. US$59+ $11 shipping is a tiny cost to solve a painful, and frequently damaging issue. The kit includes complete instructions; it’s not difficult to install, but you need to do it the right way. To get yours, use the PayPal Buy Now Button:

At this time, we are all sold out, and do not anticipate making more. Thanks everyone so much for your purchases!

In addition to the kit, you’ll want to get some anti-static spray or wipes, and maybe some small tie-wraps.

Why do you need this?

If you use a Next Wave Automation CNC Shark machine, one thing you’ll eventually come up against are the powerful static charges that accumulate on the machine. Because major structural parts of the system are made from High Density Poly-Ethylene (HDPE), the different parts are electrically insulated from each other.

That means that when a chip is cut from the bit and flung across the bed, a small electrical charge is taken from the bit and material, and added to the bed of the machine. Repeat that at 24000 RPMs, and it can quickly add up to a whole bunch of charge, building up higher and higher over time. Because the original stepper-motor ground wires connect directly to the controller PCB, that built-up charge goes first to the controller board, and only afterwards to the case ground. That “afterwards” configuration allows a significant voltage to build up on the logic ground, leading to controller board errors and often to outright failure.

So why not just short out everything together, and be done with the problem? You can…but not if you want to use the touchplate. The system relies on it being able to detect when the touchplate touches the end of the bit. If you’ve got them already connected together, well, it can’t sense the contact.

What’s a CNC operator to do? The solution is actually pretty simple: connect the spindle to the bed, but not so strongly that it disrupts the z-height sense circuit. I did some testing, and a 470 kOhm resistor works wonderfully for this. Just enough to drain off the charge, but not so much the touchplate won’t work.

In addition, a big part of why people are losing their controllers to static has to do with how NWA grounds their stepper motor cases. I won’t go into the nitty-gritty electromagnetic compatibility issues involved, but suffice it to say it’s incorrect practice to connect those three grounds directly to the logic ground of the controller PCB. This kit will fix that, by replacing the incorrect connections with ones properly designed to get rid of static without damaging the main board.

In addition to the replacement wiring, when you clean the machine and bed, I recommend you also use some anti-static spray. It’s available in lots of places, in spray and wet-wipes. It’s really just a particular type of detergent, heavily diluted in water. It’s not dish-washing detergent, but it’s also not a military secret; don’t get swindled by the high-price options. Follow this link to Amazon’s a wide selection.

Price is US$59 + $11 Shipping: $70 total (+tax)

Several have asked me for plans. I’ve recently changed my mind, and am now including the full plans for making a set. The way I’m thinking, if you’re really going to exactly duplicate what I’ve done, then you’re going to be buying something like 5 different types of crimp lugs, and over 20 feet of wire, and you have the tools and ability. Anyone who can do that wouldn’t really be stopped by not having the plans, so the plans can just make it easier for those. Similarly, some might not want to pay for a second set for their new machine, and want to make one the same or a less-complex version. I’m okay with that. I recommend that you don’t go into business selling them, not because it will somehow hurt me, but because there just isn’t any volume. I think I’ve sold a dozen kits a year.